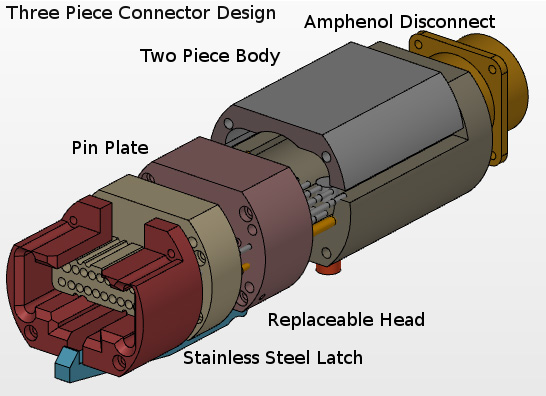

Test Connector Technology

LM3 recognizes the importance of user friendly but robust test connectors. Using 15 years of experience in connector design and manufacturing, LM3 has developed a standard three part design using 3D modeling software and a 3D printer for prototyping, that is simple yet reliable in even the most rough industrial environments. The test connectors are fabricated from a non-static plastic and are assembled with utmost care. Industrial pogo pins and sockets are included for durable connection points. The modular style, with multiple piece design, allows for an easy repair or replacement of individual parts.

Features And Specifications

Features

LM3 has committed extensive R&D to our test connector product design to address ergonomics, durability, and maintainability. For this reason, we design our connectors with a three piece construction.

Three part design:

- Removable head sockets into a pin plate for ease of maintenance.

- Pin plate connected to quick disconnect as permanent part of connector.

- Two piece body for ease of maintenance and assembly.

LM3 Technologies, Inc. has in-house capabilities to provide industrial repairable type test connectors. The test connectors are fabricated from a non-static plastic on high precision CNCs mills. Industrial pogo pins and sockets are included for durable connection points. The Modular style, with multiple piece design, allows for an easy repair or replacement of individual parts. All soldering/crimping is completed in the main connector body and is isolated from the test connector head. Termination to the test system can be done using military circular or Harting HAN disconnects.

Specifications

- Modular three piece design to increase durability and ease maintenance

- Lightweight but durable designs using 3D modeling software

- 3D printer utilized for rapid prototyping to speed development time and reduce development costs

- Production machining using CNC machine centers and speeds and feeds developed over time to ensure precise dimensional tolerances

- Pneumatic shunt removal units for testing pyrotechnic connections for their bridged and unbridged resistance.

- Metallic and non-metallic shrouds and guides to easy in mating to DUT connector

- Optional inclusion of a test connector connected sensor to restrict the start of the test cycle until the connector is connected.

- Optional LED to indicate when the connector is required based on the product under test.

- Optional Lockable latches to prevent accidental disconnects during testing.

- Wireless test connectors using built in circuit boards and bluetooth communications to host control system

Applications

LM3’s test connector products can be used to interface our or competitors’ test systems with the DUT under the following applications:

- Hand held connectors for moving lines and hard to reach locations

- Auto docking connectors for unmanned testing

- Carrier based docking for automation purposes

- Fixed connectors for improved durability

- Automated shunt bridge removal applications such as air bag testing

- Automatic locking and ejecting fixturing

- Wireless connectors for inline product testing spanning several assembly stations using our patent pending distributed testing process