Machine Vision Systems

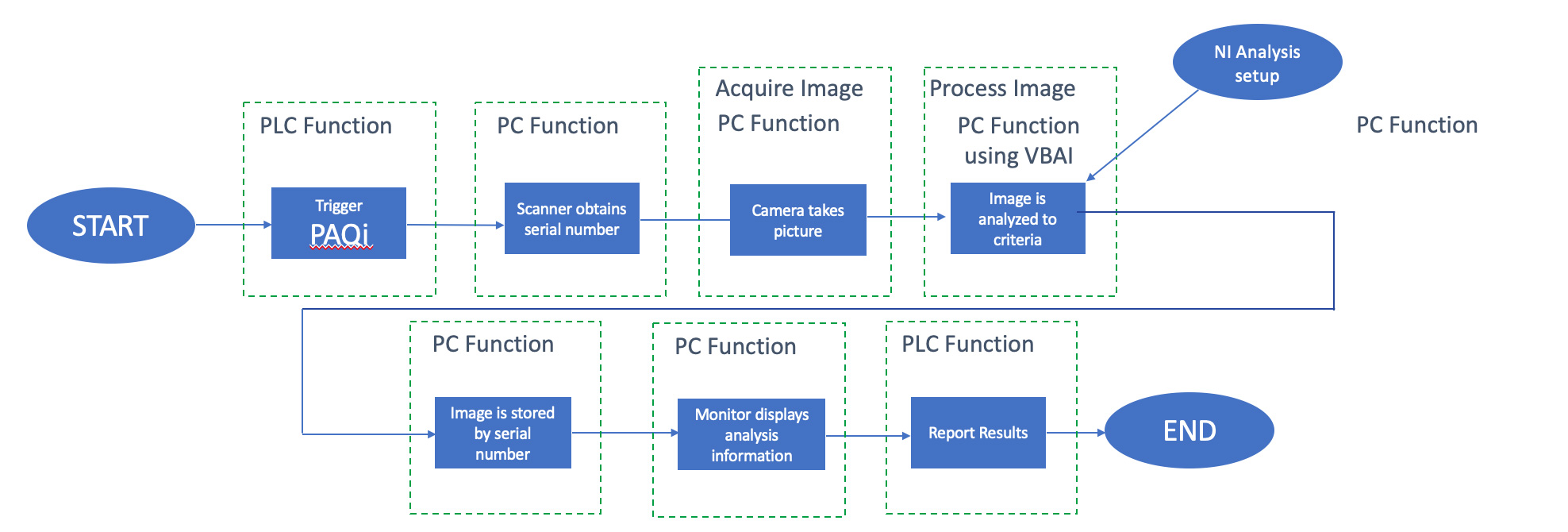

LM3's PAQi, short for picture acquisition and inspection, provides a means to capture quality control images in production for use in warranty claims as well machine vision-based inspection. The PAQi, running on Windows 10 Enterprise IoT, contains software to acquire images from any DirectShow, USB3, or GigE compatible camera as well as an API for National Instruments’ Vision Builder AI inspection software for advanced machine vision inspection. LM3's PAQi can also connect to a cloud or localized Deep Learning AI server for performing deep learning for classification and defect detection applications.

Request a Demo

LM3 is offering a limited number of free demonstrations of PAQi. Please contact us to arrange an onsite demo now.

Features And Specifications

Features

Since 2017, LM3 has committed extensive R&D to our PAQi vision system to address cost constraints that limits the wide-scale use of machine vision in production. Our PAQi with one camera is cost competitive with the standard high-resolution color smart cameras by Keyence, Cognex, Banner Engineering, and the like and is a fraction of the cost of multi-camera systems by those same suppliers. With an onboard Modbus TCP PLC, the system can interface with your production equipment using either digital IO or Industrial Communications including EthernetIP and Modbus TCP. This flexible machine vision platform contains the following standard but configurable features with the ability for customization on request:

- Acquisition and inspection triggering using the digital IO connection on an M12 circular connector or using EthernetIP communications via one of two LAN ports

- Barcode acquisition via a standard or triggered bar code scanner or a camera

- Ability to self-generate serial number for non-labeled parts

- System capable of querying part number being inspected from a SQL database or by manual selection

- Customize camera settings including exposure, brightness, contrast, gain, hue, and focal length (if auto-focus camera used) by part number or sequence step

- Ability to use HDR or WDR to obtain better quality images in difficult environments with poor lighting

- Storage of acquired and analyzed image to a local or remote storage device

- Pictures are named by serial number obtained during part number acquisition

- Acquisition and inspection results reported to station via digital outputs on an M12 circular connector or using EthernetIP communications via one of two LAN ports

- Inspection analysis done using National Instruments’ Vision Builder AI software or Deep Learning AI models

- Results reported to a PLC using industrial communications, printer, SQL Server, and/or flat file

Since 2018, LM3 has been hard at work developing a complete training, evaluation, and serving pipeline for AI based vision inspection. This groundbreaking system provides a means for using the advanced technology to solve inspection applications previously not possible using traditional machine vision at a significantly less overall cost. LM3’s AI based vision inspection solution saves customers time and money by:

- Reducing scrap

- Eliminating customer returns and paybacks

- Reducing or eliminating ineffective human inspectors

- Reducing the setup time to deploy machine vision inspection

- Reducing the expertise required to deploy machine vision inspection

- Using a machine to perform trial and error to configure the vision inspection algorithm and improve it over time. The machine runs 24/7 and only requires electricity to operate while never getting tired.

LM3 made a conscious effort to design and system capable of image acquisition and AI model based inspection on the same hardware and has a truly one of a kind system that cannot be compared.

More recently, LM3 has partnered with QCHero to develop an online training platform for training both classifier and object detection models using cloud-based hardware to speed up the training time. QCHero eliminates the need for expensive in-house hardware for model training and was developed to be user friendly to allow for use by technicians and quality engineers and not just computer scientists.

Specifications

- PC based control using the latest generation Intel Processors

- Windows 10 Enterprise OS to allow for integration with your plant network

- National Instruments Vision Builder AI used for standard machine vision inspection including machine learning algorithms

- Deep Learning AI API for deep learning applications including classification and object/defect detection

- Custom and TFServer model servers onboard PAQi for serving multiple models without the need for special/expensive hardware as well as to transfer large images on the shop floor network for doing inspection. Having the model server on the PAQi reduces the inspection time.

- Software for acquiring images from DirectShow, USB3, and GigE compatible cameras

- Onboard PLC for providing a digital interface with (2) digital inputs and (4) digital outputs for machine control such as part sensing and clamping prior to inspection. The PLC also allows you to customize the interface with the inspection station

- Up to four USB3 ports for interfacing with USB3 cameras up to 42MP in resolution

- One Thunderbolt connector for cameras, storage drives, or network adapters

- One Modbus TCP port to exchange inspection results with your MES system

- Built in EthernetIP drivers for interfacing with your shop floor network

- Two modes of operations to acquire and inspect images in a fixed position camera arrangement or a step mode for inspecting multiple part features using a robot to position the camera

- Software interface for traditional USB barcode scanners or vision-based barcode reading for traceability purposes

- Software interface for printing a results barcode

- Software interface for storing results to SQL

Applications

- Image acquisition for storing warranty photos for traceability purposes

- Robotic inspection

- Part presence and/or orientation detection

- Part tracking

- Color or object classification and defect detection using machine or deep learning technology

- Inspection station control including part sensing and capturing

- OCR and 1D/2D barcode acquisition and inspection

- Industry specific application include:

- End of line verification to confirm part is assembled correctly

- Inline verification to confirm correct part is assembled in the correct position and orientation

- Defect detection on molded parts including short shots, flow lines, sink marks, vacuum voids, surface delamination, weld lines, warping, burn marks, jetting, and flash

- Color matching to confirm the correct set of parts are assembled

- Gap inspection for seam lines on assembled parts

- Thread color inspection and proper alignment detection

- Feature measurement and inspection for ultrasonic welding applications

- Inspecting machine state prior to cycling to prevent damaged caused by parts or debris in path of moving parts

- Verification of label positioning and readability

Videos

Videos examples of the PAQi detection:

Hog Ring Detection

Weld Integrity Inspection

Molded Component Defect Detection

Large Single Camera Multi-part Presence Inspection

GP12 Inspection

Product Documents and Presenations

A list of product documents and presentations are available to download below:

| Name | Format | Link |

|---|---|---|

| PAQi Line Card | Download / View | |

| PAQi Presentation with DLOD | Download / View | |

| PAQi Object Detection - Hog Rings | Download / View | |

| PAQi Defect Detection - Molding | Download / View | |

| PAQi Object Detection - Push Pins | Download / View | |

| PAQi Object Detection - Chrome Grill | Download / View | |

| QCHero Presentation | Download / View | |

| PAQi Object Detection with Color Classification - Office Chair Components | Download / View |