System Validation and Calibration

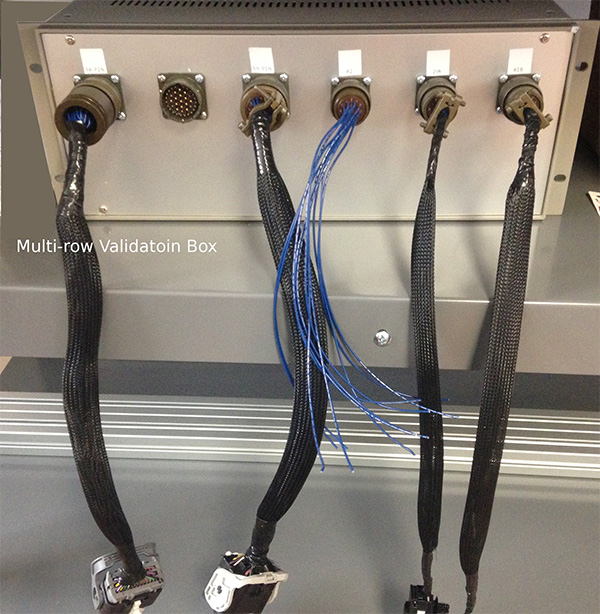

Since manufacturing its first test systems, LM3 quickly recognized the need to be prove functionality through careful calibration and validation, and therefore began manufacturing validation systems for functionality verification. LM3’s designs include simple OK/NOK boxes and completely automated validation/calibration systems capable of interacting with its testing software to provide a full report of functionality in the form of a Gage R&R as well as a means for calibrating the test channels and lasers used for displacement measurements.

Features And Specifications

Features

In order to provide these services to our customers for test systems supplied by other companies, LM3 is currently working for ISO 17025 accreditation. Achieving the ISO 17025 standard will establish LM3 as a calibration laboratory and improve upon the our current ISO 9001 Quality System in one of our core competencies: production based functional testing.

Specifications

- Fully automated validation systems capable of “testing the tester”

- Fully automated calibration systems capable of calibrating the tester

- Manually operated OK/NOK boxes for use in between shift verification of tester functionality

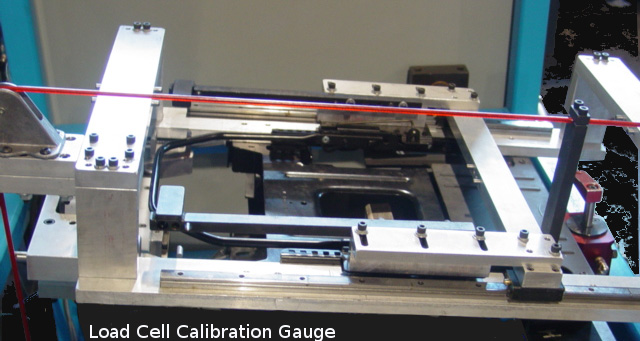

- Manual test channel calibration using procedures developed to calculate linear coefficient using resistors for electrical measurements, scales or weights for force measurements, and gauge blocks for displacement measurements.

- Data analysis tools used in conjunction with the above physical tools to run gage R&R studies to prove measurement capability.

Applications

Calibration and validation are the only means for verifying a test system’s capabilities. LM3 uses a combination of gauges and analysis software to provide verification of capability for the following applications:

- Electrical measurement systems and multi-meters

- Pressure sensors and flow meters

- Scales and load cells

- Torque and fastening systems

- Accelerometers

- Displacement LVDT and Lasers