Software Solutions

LM3 applies open source and custom developed software solutions to improve our customers’ performance through data acquisition, data management, data analysis, technical collaboration tools, and shop floor controls. LM3 has been developing software since its inception including but not limited to application development for the following manufacturing needs:

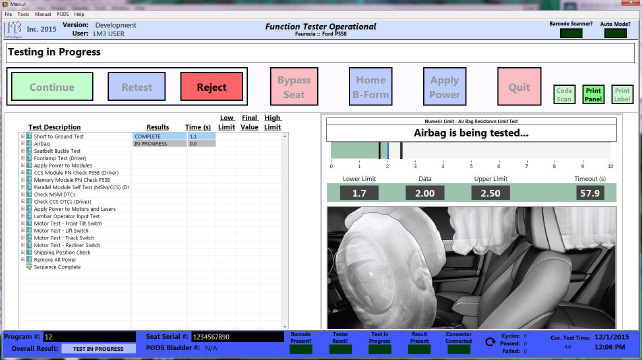

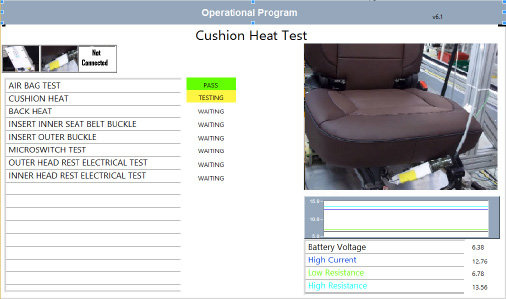

- Complete test management packages for end of line testing for any type of DUT

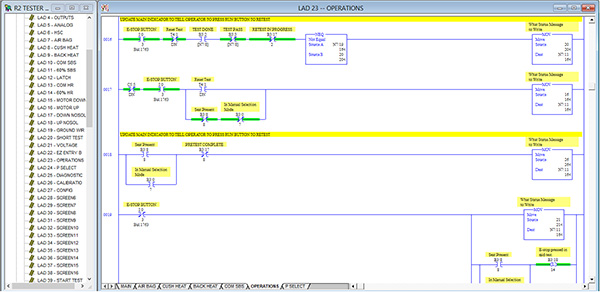

- Automation applications including PLC programming, SCADA, and motion control

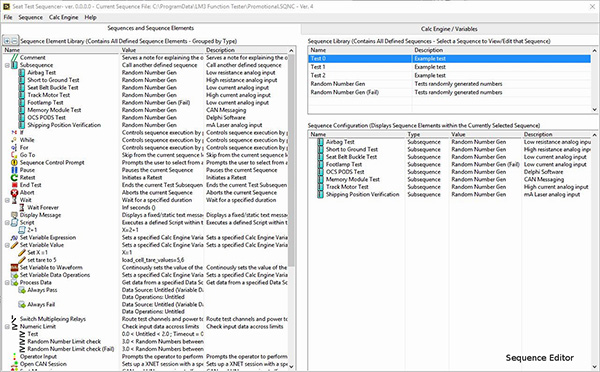

- Sequencer software to allow for flexible sequencing for MES and testing applications

- Drivers and adapters for integrating devices with diverse functional specifications

- Software for patching holes in existing software systems

- Complete MES package development

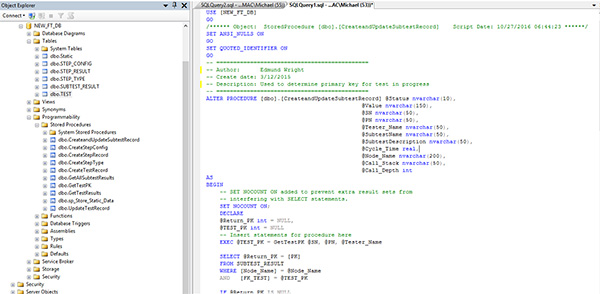

- SQL storage and query systems for traceability and conformity

- Data analysis and report tools

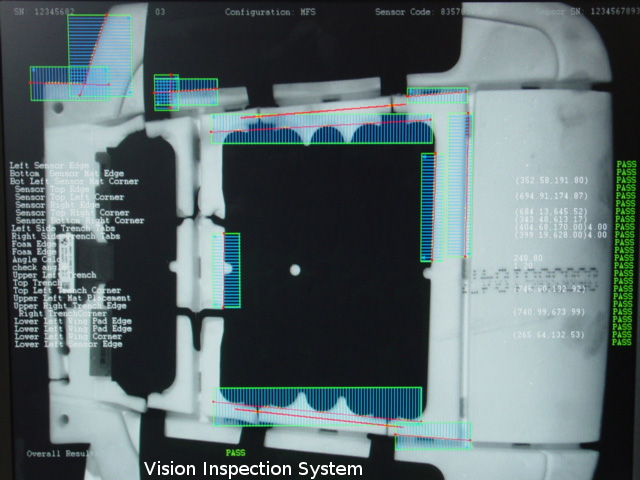

- Motion control and vision inspection

- HMI software development

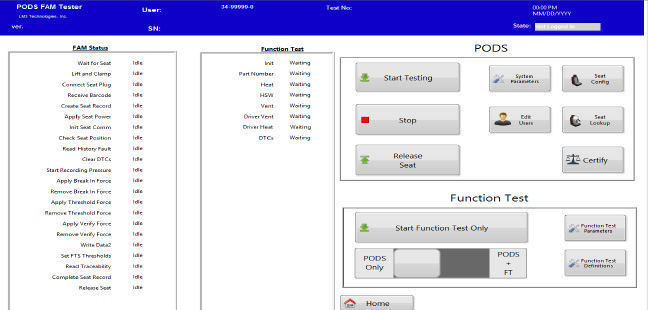

Contracted to make a multi station end of line tester for Futuris Seating, a seat manufacturer for Tesla Motors, LM3 recently invested more than 2000 engineering hours for R&D on a generalized test sequencer capable of both Delphi PODS calibration and end of line function testing. Designed for the automotive industry, the software package is hardened to run in a 24/7 manufacturing environment. Based on NI’s TestStand, LM3’s Test Sequencer Software is a test management package that eases tester deployment and long term upgrades by allowing custom sequence configuration using an intuitive sequence editor. Because LM3 owns the source code, long term continuous improvement and unlimited customization is always within reach.

Features And Specifications

Features

LM3’s Test Management Software provides the following tools to configure, certify, process, and diagnose your test requirements:

- Configuration Editor

- Operational Program Interface

- Diagnostics Manager

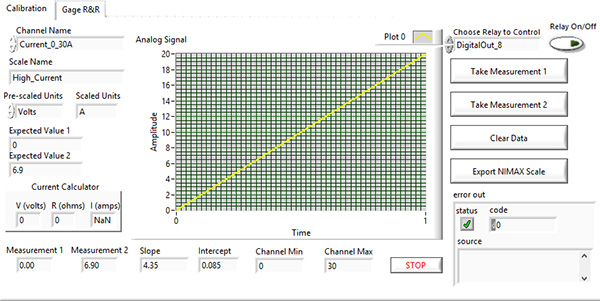

- Calibration and Certification Manager

- MES Interface and Storage Options

- Data Analysis Manager

LM3’s first (1999) and recent version of its testing software was and is developed using National Instruments LabVIEW development system and has been continuously improved over the last 17 years. The capabilities of NI LabVIEW have proven to be less complex and more adaptable than fragmented automation packages provided by similarly marketed development systems.

For continuity sake for manufacturers using our legacy testing hardware, LM3 modified its original seat testing software package to work with its latest version hardware package. This version of software modularized the connection to DAQ hardware for greater longer term flexibility in hardware. LM3 also continues to develop its PLC based tablet mHMI software for additional functionality including storing test results to a remote SQL database. Furthermore, LM3 has developed a stand alone software application for use with our version 5 hardware package in order to perform Delphi PODS calibration along with climate control function testing.

Our key areas of expertise include:

- Machine Vision Analysis for Quality Control including Deep Learning

- SQL Operational and Warehouse Database Design

- Generating KPIs through Data Acquisition from PLCs and Manufacturing Machines

- Server Virtualization

- Mobile Data Acquisition and Machine Control including LPA and First Piece and Safe Launch Audits

- Measuring Manufacturing Performance Using OEE and/or OLE

- Pick to Light Systems

- End of Line Quality Control Systems

- Manufacturing KPI Dashboard Customization

- SQL Services Reporting

- Test Management Software

- General System Integration

Specifications

- PC based software centered around NI’s Labview Development System

- Advance PLC programming for automation and mixed signal applications

- SCADA programming

- MySQL and MSSQL DB design and stored procedure development

- Manufacturing Execution Systems(MES) including innovative systems to adapt buffer based manufacturing to Just In Time(JIT) manufacturing requirements

- General configurable sequencing software for use in traceability and conformity applications

- Statistical analysis tools for Quality Control Systems(QCS)

Applications

LM3’s software products and services can be used for any industrial or manufacturing software need:

- PC and PLC based sub-assembly testing stations

- Fully configurable vision inspection applications

- Final induction application for verifying the existence of traceability data prior to shipment

- Fastening control software

- Build to replace MES to adapt a buffer based production system with a JIT end user

- Table based HMI software for PLC applications

- Sequencing software for packaging lines

- Generalized sequencer for testing applications

- Delphi PODS calibration applications

- Sound and vibration testing software

- End of line 100% functional testing software using a sequencer or dedicated application

Product Documents and Presentation Files

A list of product documents and presentation files are available to download below:

| Name | Format | Link |

|---|---|---|

| mDAQ: Mobile Data Collection Solution | PPTX | Download / View |

| OEE Systems Presentation | PPTX | Download / View |